Introduction:

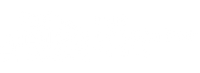

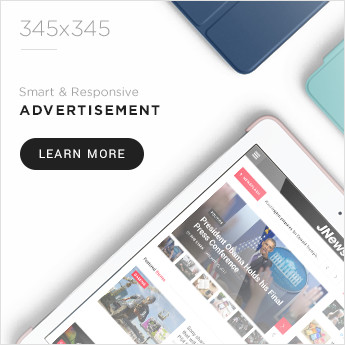

Just-in-Time (JIT) logistics strategy is a lean approach to managing the flow of goods and materials within a supply chain. This method aims to optimize efficiency by ensuring that items are delivered precisely when they are needed, reducing excess inventory and associated costs. While this approach has become increasingly popular in recent years, it is important to weigh the benefits and drawbacks of adopting a JIT logistics strategy to determine if it is the right fit for your business.

Pros of Implementing a Just-In-Time Logistics Strategy

- Reduced Inventory Costs: One of the primary benefits of JIT logistics is that it allows businesses to minimize their inventory costs. By only ordering goods when they are needed, companies can reduce the amount of stock they need to store. This can lead to significant savings in warehouse and storage expenses.

- Improved Efficiency: JIT logistics also helps improve overall efficiency within a supply chain. By ensuring that items are delivered just in time, businesses can minimize waste and optimize their operations. This can lead to faster turnaround times, increased productivity, and greater customer satisfaction.

- Enhanced Agility: Another advantage of JIT logistics is that it can help businesses become more agile in responding to changing market conditions. By keeping inventory levels low and ordering items as needed, companies can more quickly adapt to changes in demand, pricing, or supply chain disruptions.

Cons of Implementing a Just-In-Time Logistics Strategy

- Greater Reliance on Suppliers: JIT logistics requires a high level of coordination and communication with suppliers. Companies must have strong relationships with their suppliers to ensure that items are delivered on time and meet the necessary quality standards. This can be challenging for businesses that work with a large number of suppliers or have complex supply chains.

- Increased Risk of Stockouts: Because JIT logistics relies on ordering items only when they are needed, there is an increased risk of stockouts. If a supplier is unable to deliver an item on time or at the expected quality, it can disrupt the entire supply chain and lead to delays, lost sales, or even reputational damage.

- Potential Disruption to Operations: JIT logistics requires precise planning and execution to work effectively. If any part of the supply chain breaks down, it can cause delays or disruptions to operations. This can be especially problematic for businesses that have tight production schedules or rely on just-in-time delivery to meet customer demand.

Just-in-Time logistics is a popular approach to managing supply chain operations that has many potential benefits. However, it is important to weigh these benefits against the potential drawbacks to determine if it is the right fit for your business. By carefully evaluating your operations and supply chain, you can make an informed decision about whether implementing a JIT logistics strategy is the best way to optimize your efficiency and reduce costs.

How to Determine If JIT Logistics is Right for Your Business

Before deciding to implement a JIT logistics strategy, it is important to assess whether it aligns with your business goals, operations, and supply chain. Here are some factors to consider when evaluating whether JIT logistics is right for your business:

- Evaluate Your Production Processes : Consider how your production processes work and how JIT logistics may impact them. For example, if you have a long lead time for raw materials or components, JIT logistics may not be the best fit as it requires a shorter lead time.

- Assess Your Supplier Relationships : Evaluate the strength of your supplier relationships and determine if they are capable of meeting the requirements of a JIT logistics strategy. If you work with multiple suppliers, it may be more challenging to coordinate delivery schedules and ensure consistent quality.

- Analyze Your Inventory Costs: Calculate your current inventory costs and determine if a JIT logistics strategy could lead to significant savings. Be sure to consider not only the direct costs of storing and managing inventory, but also the potential benefits of reduced waste and improved efficiency.

- Consider Your Customers’ Needs : Think about your customers’ needs and expectations. If they require fast delivery times or frequently change their orders, a JIT logistics strategy may be a good fit. However, if they are willing to wait longer for their orders, JIT logistics may not provide significant benefits.

- Evaluate the Risks : Assess the potential risks associated with implementing a JIT logistics strategy. Consider factors such as supplier reliability, the complexity of your supply chain, and the potential for disruptions or delays.

How to Successfully Implement a JIT Logistics Strategy

If you have decided that implementing a JIT logistics strategy is the right move for your business, there are several steps you can take to ensure its successful implementation:

- Build Strong Relationships with Suppliers : JIT logistics relies heavily on suppliers, so it is important to build strong relationships with them. This can involve regularly communicating with them, providing them with forecasts and schedules, and working together to identify potential issues and solutions.

- Use Technology to Streamline Processes : Implementing technology such as a Warehouse Management System (WMS) or Enterprise Resource Planning (ERP) can help streamline JIT logistics processes. These systems can provide real-time information on inventory levels, orders, and delivery schedules, making it easier to manage supply chain operations.

- Develop a Contingency Plan : While JIT logistics can be highly effective, it is important to have a contingency plan in place in case of disruptions to your supply chain. This can involve identifying alternative suppliers or developing backup inventory plans to ensure that you can continue to meet customer demand in the event of a disruption.

- Train Your Staff : JIT logistics requires a high level of coordination and precision, so it is important to ensure that your staff are fully trained and understand the processes involved. This can involve providing training on inventory management, supply chain coordination, and contingency planning.

- Continuously Monitor and Adapt : JIT logistics requires continuous monitoring and adaptation to ensure its ongoing effectiveness. Regularly reviewing your supply chain operations, identifying potential areas for improvement, and adapting your processes as necessary can help ensure that your JIT logistics strategy remains effective over time.

Conclusion:

Implementing a Just-In-Time (JIT) logistics strategy can offer significant benefits for businesses, including reduced inventory costs, improved efficiency, and enhanced agility. However, it is important to carefully evaluate the potential drawbacks, such as increased reliance on suppliers and the risk of stockouts or disruptions to operations. By assessing your business goals, operations, and supply chain, you can determine if a JIT logistics strategy is the right fit for your business.